Introduction[spacer height=”10px”]

At GBRF, our woven fabrics can be delivered in several weaving patterns. What weaving pattern works best, depends on the application of the product. Do you require good stability, does the fabric need good drape, do you require a smooth surface, do you need maximum strength, do you require good permeability, do you have thickness requirements?[spacer height=”20px”]

Following are the weave patterns GBRF commonly weaves:[spacer height=”20px”]

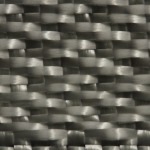

Plain Weave[spacer height=”5px”]

A well balanced fabric with excellent stability and good porosity. This weave does not drape well, and because the weft and warp have many interactions, strength is lower. This weave gives the cleanest edges when cut. It is the thickest of our common weaves. Because of crimp the surface is wavy. Because of many tight spots wet-out is slower. When heavy yarns (e.g. roving) is used, we weave a basket pattern, which is a plain weave with 2 strands instead of one in both directions. This reduces crimp and improves strength and wet-out. If a fabric of a certain weight is required, and high stability is demanded, consider a tighter weave with thinner strands.

A well balanced fabric with excellent stability and good porosity. This weave does not drape well, and because the weft and warp have many interactions, strength is lower. This weave gives the cleanest edges when cut. It is the thickest of our common weaves. Because of crimp the surface is wavy. Because of many tight spots wet-out is slower. When heavy yarns (e.g. roving) is used, we weave a basket pattern, which is a plain weave with 2 strands instead of one in both directions. This reduces crimp and improves strength and wet-out. If a fabric of a certain weight is required, and high stability is demanded, consider a tighter weave with thinner strands.

[spacer height=”20px”][spacer height=”5px”]Twill[spacer height=”5px”]

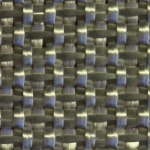

This fabric is recognized by a distinct diagonal pattern. Twills come in different configurations given as e.g. 2×2, meaning each warp and weft end goes over and under 2 ends. Wet-out and drape is better than plain weave but stability is lower especially in higher twills. Crimp is reduced resulting in a smoother thinner fabric with improved strength.

This fabric is recognized by a distinct diagonal pattern. Twills come in different configurations given as e.g. 2×2, meaning each warp and weft end goes over and under 2 ends. Wet-out and drape is better than plain weave but stability is lower especially in higher twills. Crimp is reduced resulting in a smoother thinner fabric with improved strength.

[spacer height=”20px”][spacer height=”5px”]Satin[spacer height=”5px”]

Satin weaves have a reduced number of cross overs. We weave 4 and 8 harnas satin weaves. This style is has great drape and wet-out, but stability is low and front and back are not symmetrical, but turned 90 degrees. This can be a problem when multiple layers of fabric are used. Because of low crimp, strength is best among the different patterns predominantly in the warp direction while the other face has fibres running predominantly in the weft direction. Care must be taken in assembling multiple layers of these fabrics to ensure that stresses are not built into the component through this asymmetric effect.

Satin weaves have a reduced number of cross overs. We weave 4 and 8 harnas satin weaves. This style is has great drape and wet-out, but stability is low and front and back are not symmetrical, but turned 90 degrees. This can be a problem when multiple layers of fabric are used. Because of low crimp, strength is best among the different patterns predominantly in the warp direction while the other face has fibres running predominantly in the weft direction. Care must be taken in assembling multiple layers of these fabrics to ensure that stresses are not built into the component through this asymmetric effect.

[spacer height=”20px”][spacer height=”5px”]Mock Leno[spacer height=”5px”]

We weave this pattern for applications that require thickness, while maintaining permeability for good wet-out. The fabrics are usually much heavier than the other weaves and have a wavy surface. They have good strength, but do not have good drape.

We weave this pattern for applications that require thickness, while maintaining permeability for good wet-out. The fabrics are usually much heavier than the other weaves and have a wavy surface. They have good strength, but do not have good drape.

[spacer height=”20px”][spacer height=”5px”]Uni-Directional[spacer height=”5px”]

Uni-directional fabrics have most yarn running in one direction. These are fabrics were the strength demand is in one direction only. Most uni-directional fabrics have low stability.. This can be improved by placing hot melt strands or weave the thin yarn with a leno motion. Both will stabilize the fabric, but it will never be as good as one of the other fabrics. Stability does improve with a tighter weave.[spacer height=”20px”]

Uni-directional fabrics have most yarn running in one direction. These are fabrics were the strength demand is in one direction only. Most uni-directional fabrics have low stability.. This can be improved by placing hot melt strands or weave the thin yarn with a leno motion. Both will stabilize the fabric, but it will never be as good as one of the other fabrics. Stability does improve with a tighter weave.[spacer height=”20px”]

[spacer height=”5px”]

[spacer height=”5px”]What glass works for you:[spacer height=”5px”]

For our light weight fabrics we commonly use E-glass. E-glass has great properties for most applications. However, if you have special strength needs we can supply you material made with S2 glass. It is expensive, but if you require high strength and higher temp applications, S2 may be for you.

GBRF also weaves basalt based glass. This glass is very strong, very resistant to fatigue failure and can be used in very high temp applications. Our products are presently used in high temperature filtration applications. However it is also expensive, and it does not wet out like glass but remains visible in the resin.

For our heavier weight fabrics we offer E-glass and OCV’s Advantex glass. Advantex glass is very similar to ECR glass and it has great corrosion resistance properties. It is comparable in price to E-glass.[spacer height=”20px”]

Aramid Fiber[spacer height=”5px”]

GBRF uses Aramid Fiber made by Dupont, which is world wide known as Kevlar®. Kevlar® is very strong, very wear resistant, low weight and is not inflammable. Our Kevlar® products are mostly used in the sporting goods market, but applications are very wide spread. It is more expensive than glass.[spacer height=”20px”]

Carbon fibers[spacer height=”5px”]

Carbon is extremely strong, is conductive, has good high temperature properties and is very low in weight. Our products go into the sporting goods market, but can be used in many other applications. It is more expensive than glass.